Smart choice for cost reduction

Economical level adjustment screw

Low price, high quality, short lead time

Product Features

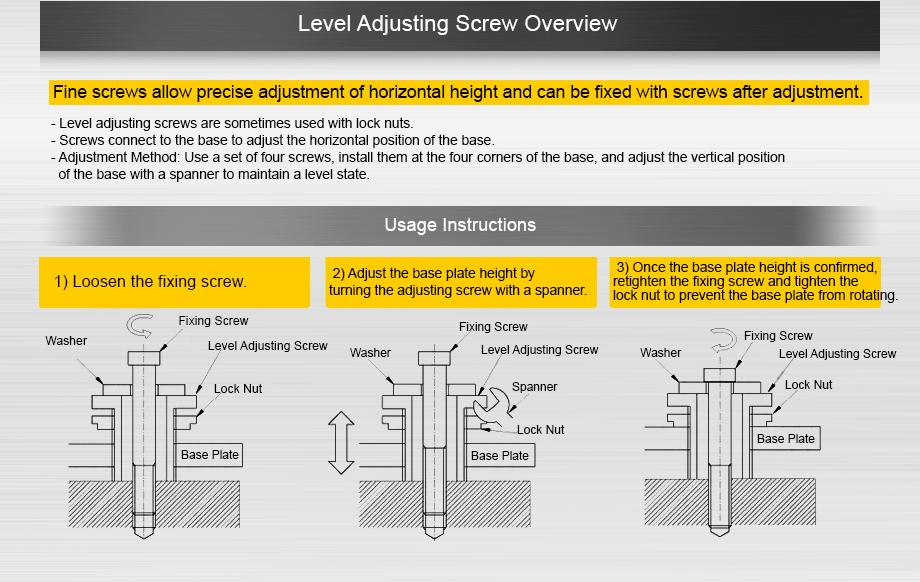

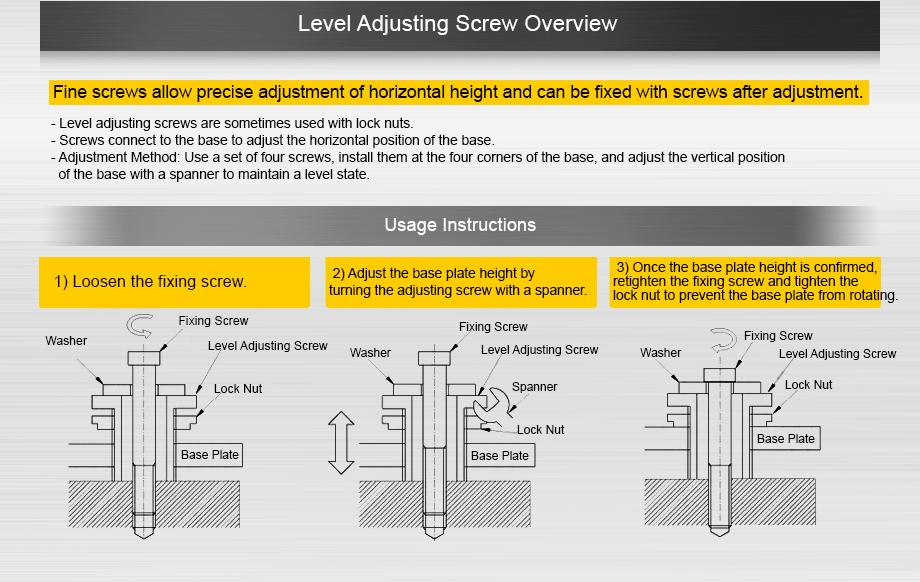

Level adjustment screw overview

The thin screw allows for precise adjustment of the horizontal height, and can be fixed with a screw after adjustment.

- The level adjustment screw is sometimes used with a lock nut.

- Connect the screw to the base to adjust the horizontal position of the base.

- Adjustment method: Use 4 as a set, install them on the 4 corners of the base, and use a spanner to adjust the upper and lower position of the base to maintain a horizontal state.

How to use

1) Loosen the fixing screw.

2) Adjust the height of the base by turning the adjustment screw with a spanner.

3) After the height of the base is confirmed, tighten the fixing screw again, and then tighten the lock nut to prevent the base from rotating.

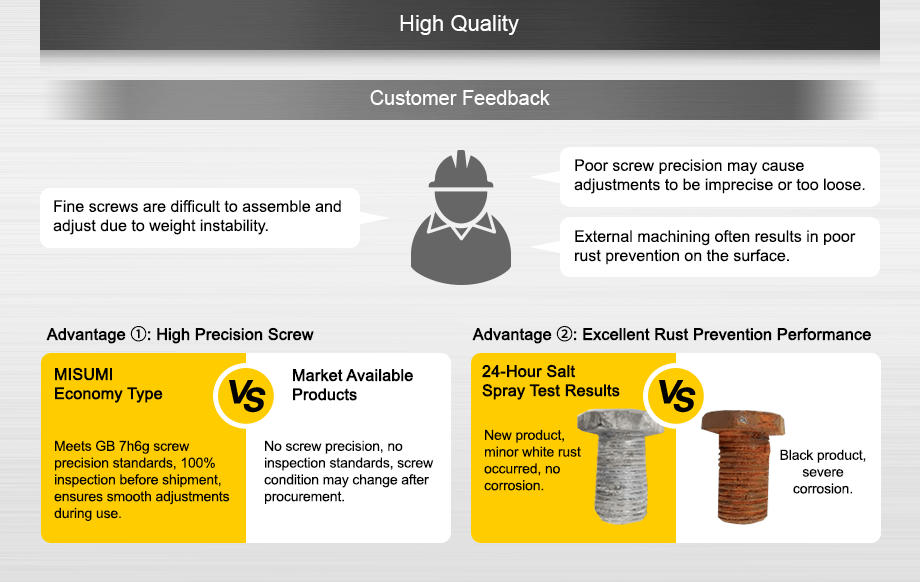

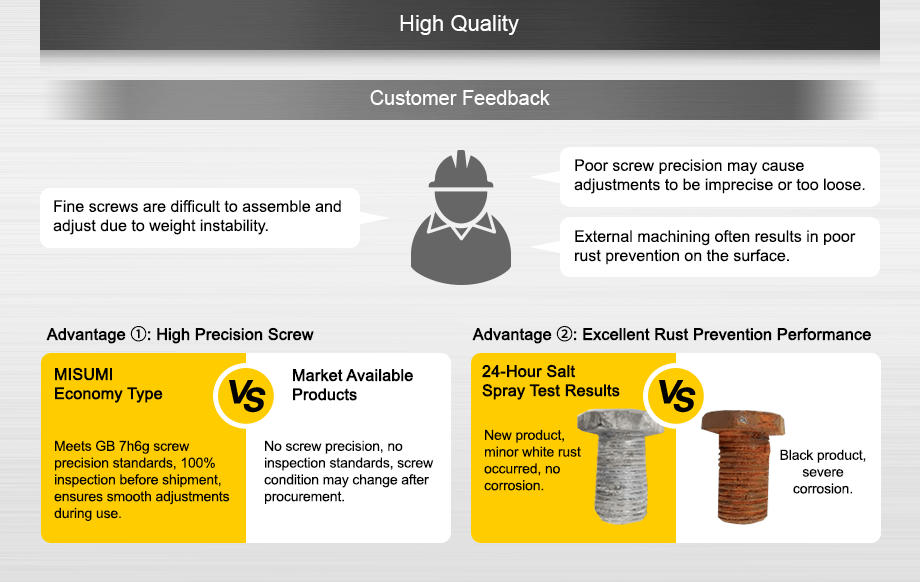

High quality

Customer feedback

Fine screws are often scratched, making assembly and adjustment difficult.

The screw precision is poor, making adjustment difficult or too loose.

Most outsourced products have a black surface treatment, which does not provide good rust prevention.

Advantage ①: High-precision screw

- Misumi economic type

-

Meets GB 7h6g screw precision

Full inspection before shipment

Ensures smooth adjustment during use

VS

- Market distribution product

-

No screw precision

No inspection standard

Screw damage found after product receipt

Advantage ②: Excellent rust prevention performance

- 24-hour salt fog test results

-

New product

Slight whitening

No corrosion

VS

Black salt product

Serious corrosion

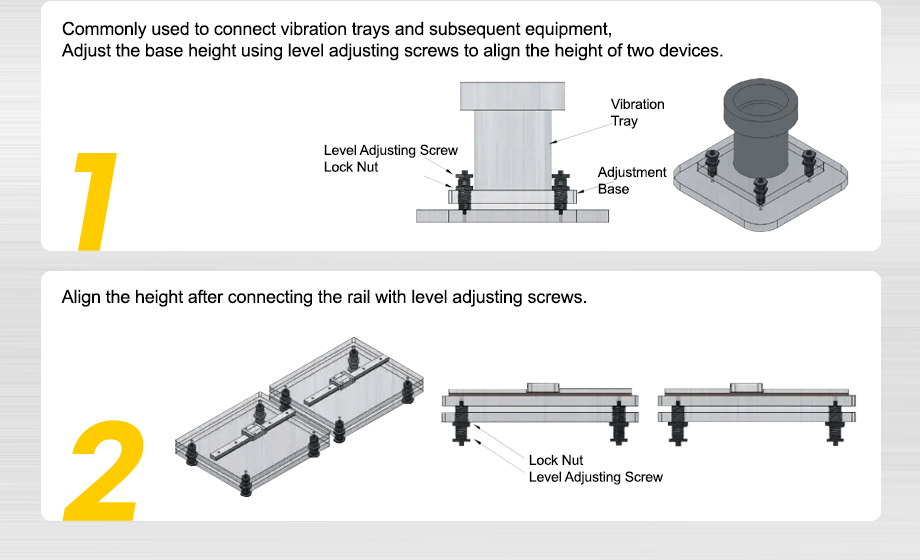

Use Cases

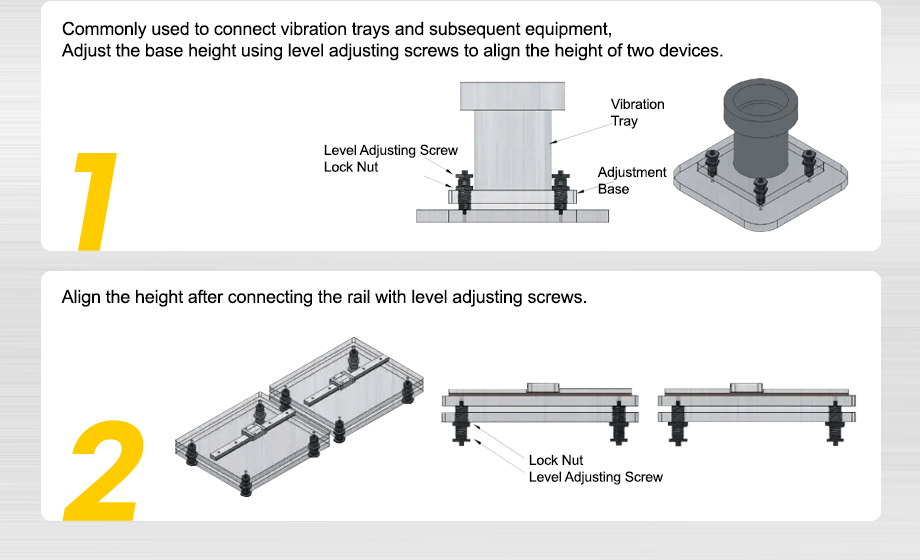

1. It is widely used in the connection of vibration trays and subsequent process equipment, and the height between the two devices is adjusted by adjusting the height of the bottom plate with a level adjustment screw.

2. The height after connecting the rails is matched with a level adjustment screw.

Recommended Products

Note: Please check the current specification, price and delivery date again from the product page.