(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

- inCAD Library Home

- > No.000045 Simplified Hand Press Unit

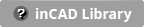

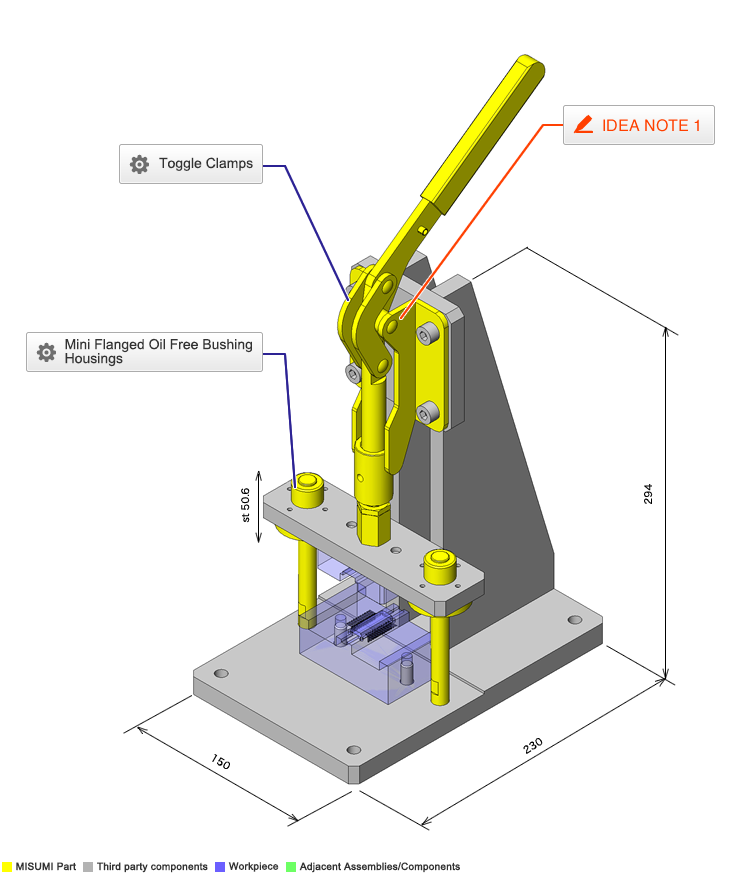

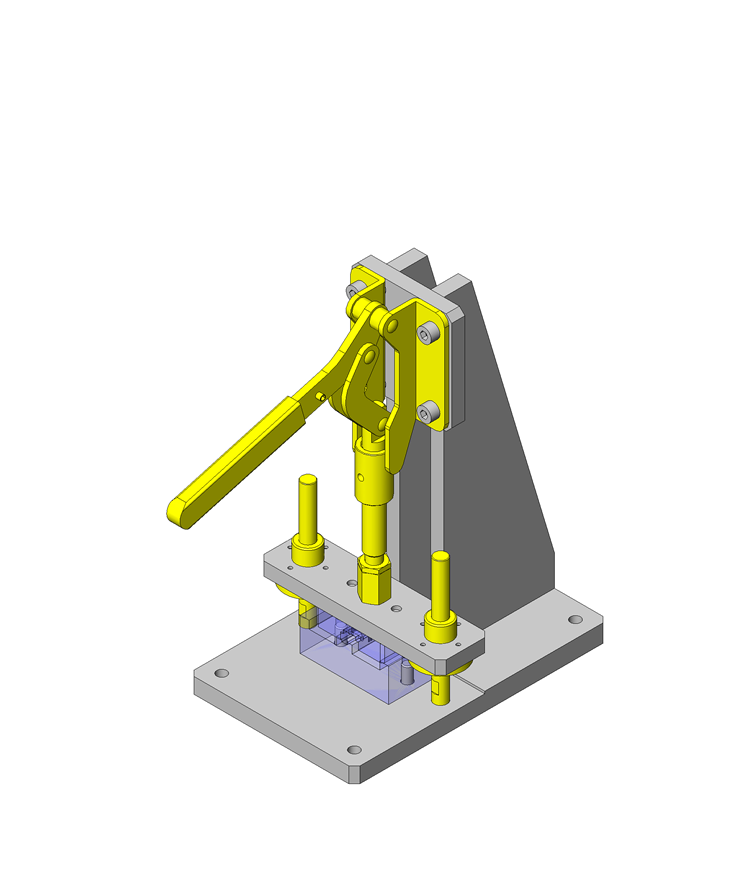

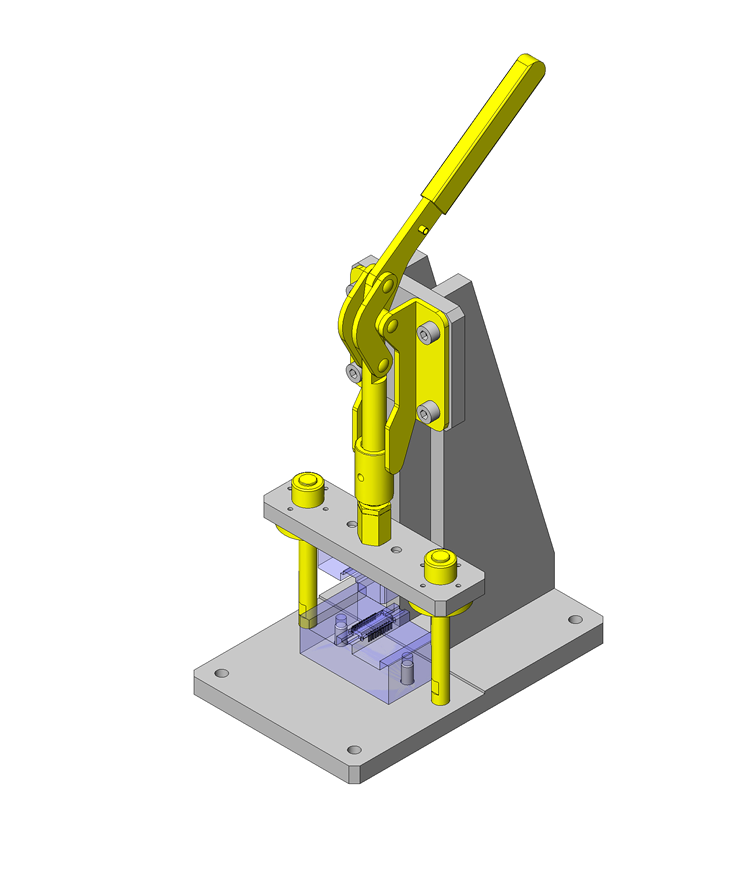

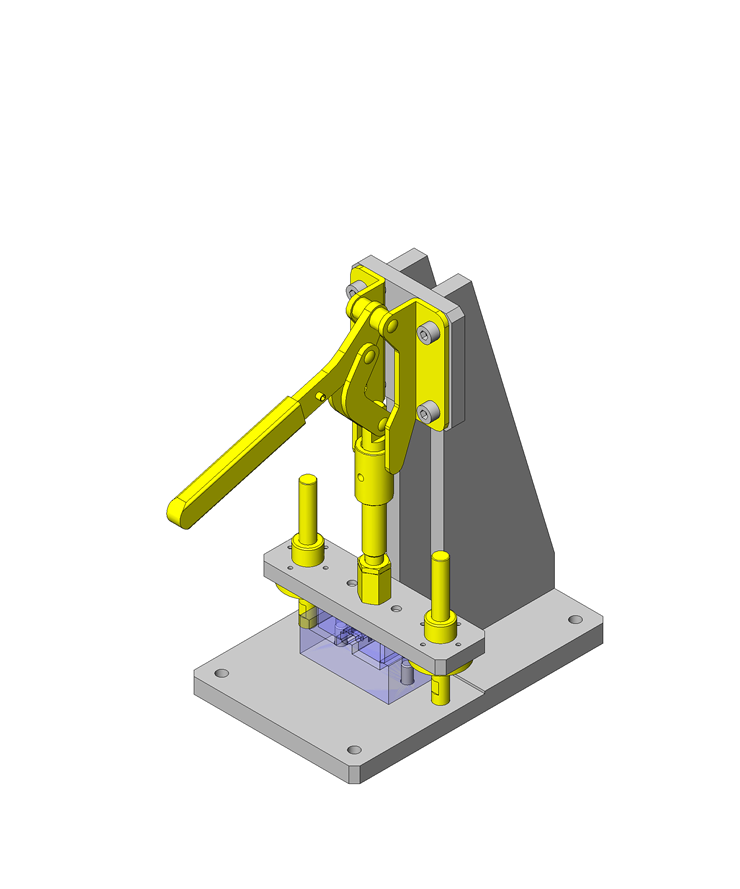

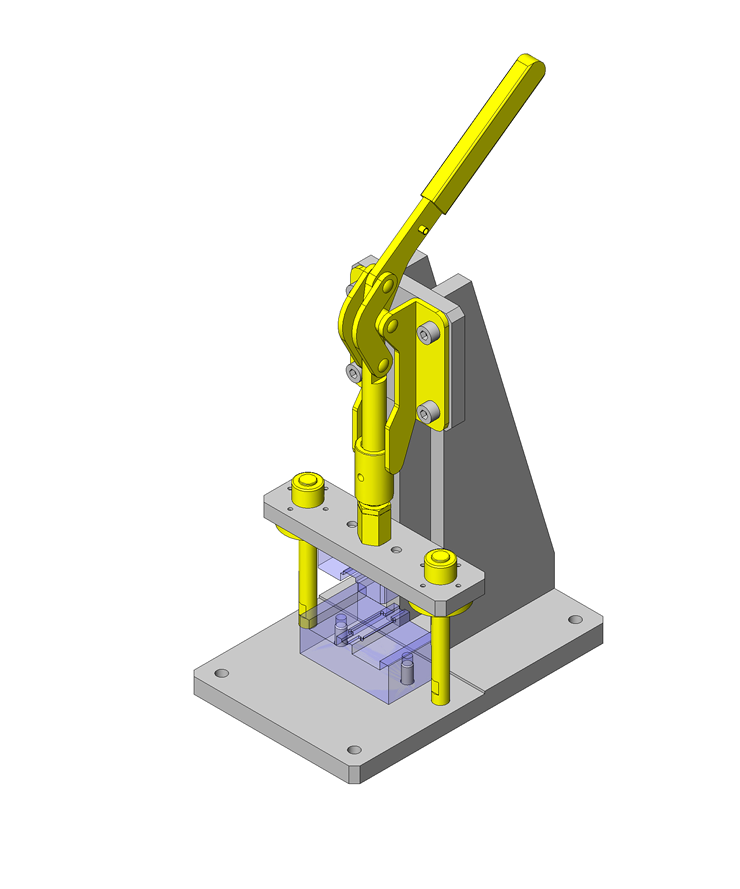

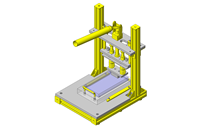

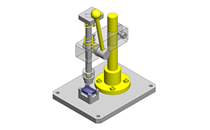

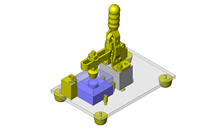

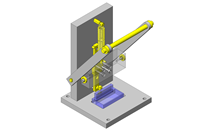

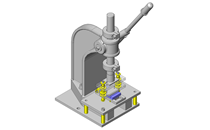

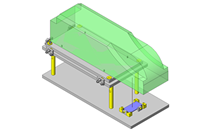

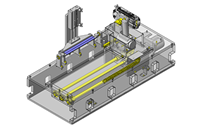

No.000045 Simplified Hand Press Unit

48

48

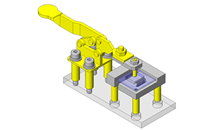

Simplified hand press unit utilizing toggle clamp.

Relevant category

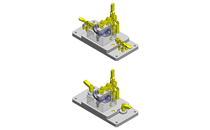

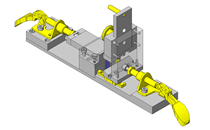

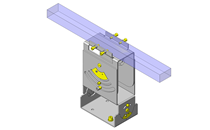

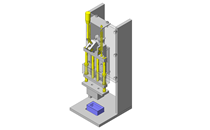

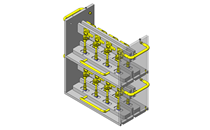

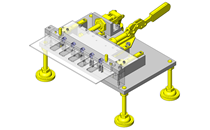

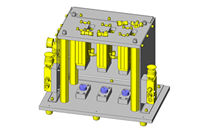

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

- Simplified hand press utilizing toggle clamp.

- Pressure is applied to the forming mold using a horizontal press unit mounted in a vertical orientation.

Points for use

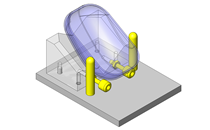

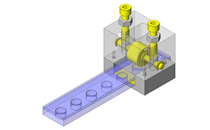

- Manual operation for small-lot production.

Target workpiece

- IC (with legs to be formed).

Design Specifications

Operating Conditions or Design Requirements

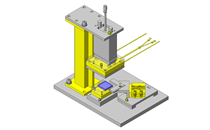

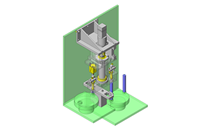

- Base: W150 x D230mm

- Overall height: 485 (max)

- Toggle clamp stroke: 50.6mm

Required Performance

- Positioning accuracy: ±0.5mm

- Push force: 3000 N or higher

Selection Criteria for Main Components

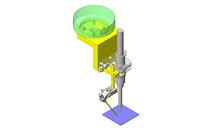

- Toggle clamp

- A toggle clamp is selected to achieve a long stroke and a high clamping force.

Design Evaluation

Verification of main components

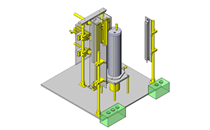

- Since the required load may increase based on the operation being performed, the toggle clamp selected has a higher clamping force then required for the initial load.

- At the same time, a toggle clamp with a large handle exhibiting good workability is selected.

- If load control is necessary, trial and error in preliminary testing is required.

Other Design Consideration

- As the lever positions in the released and pressed state affect the workability, attention needs to be paid to the lever positions in the design.

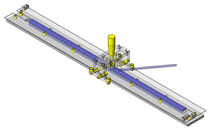

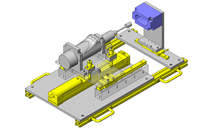

Explore Similar Application Examples

Page

-

/

-