(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

- inCAD Library Home

- > No.000076 Pallet Centering Mechanism

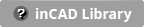

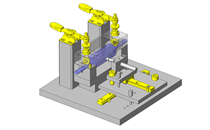

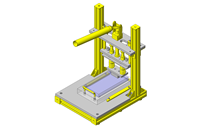

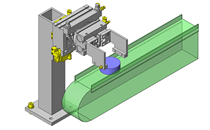

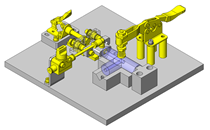

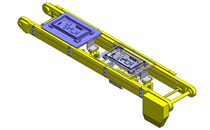

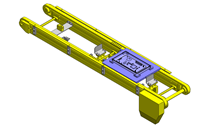

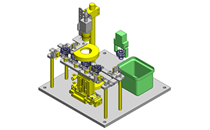

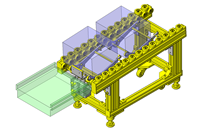

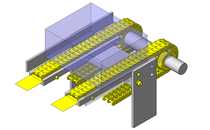

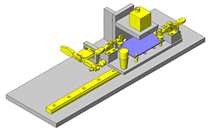

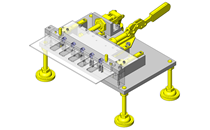

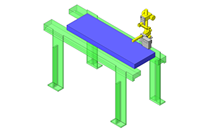

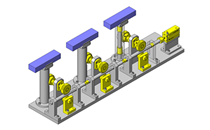

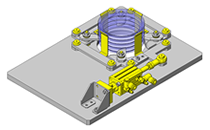

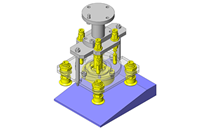

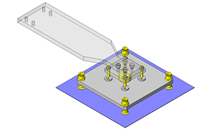

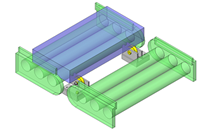

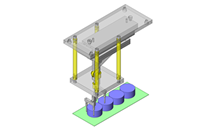

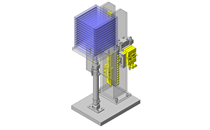

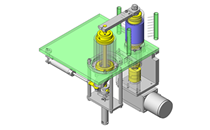

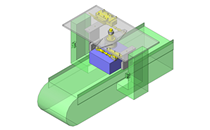

No.000076 Pallet Centering Mechanism

24

24

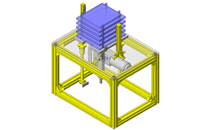

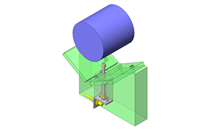

4 direction simultaneous clamping with a cylinder and a linkage mechanism.

Relevant category

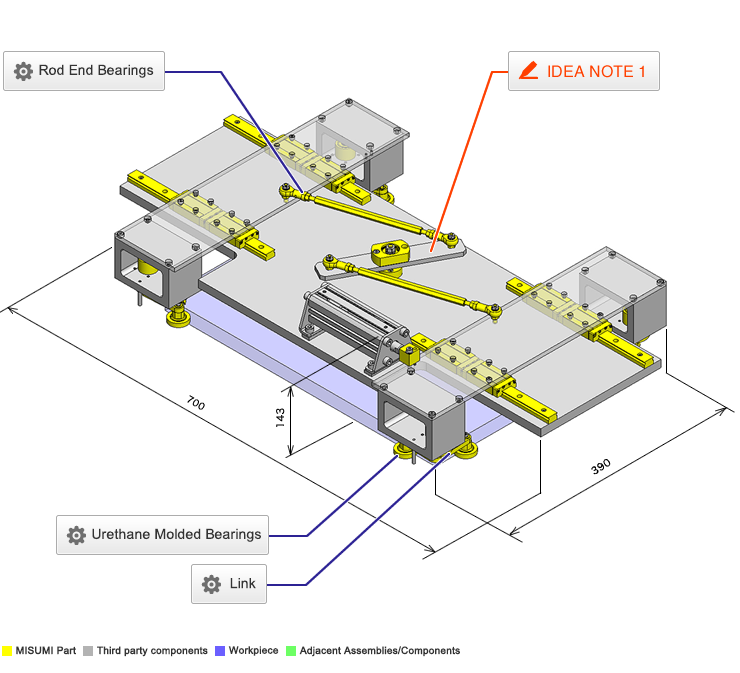

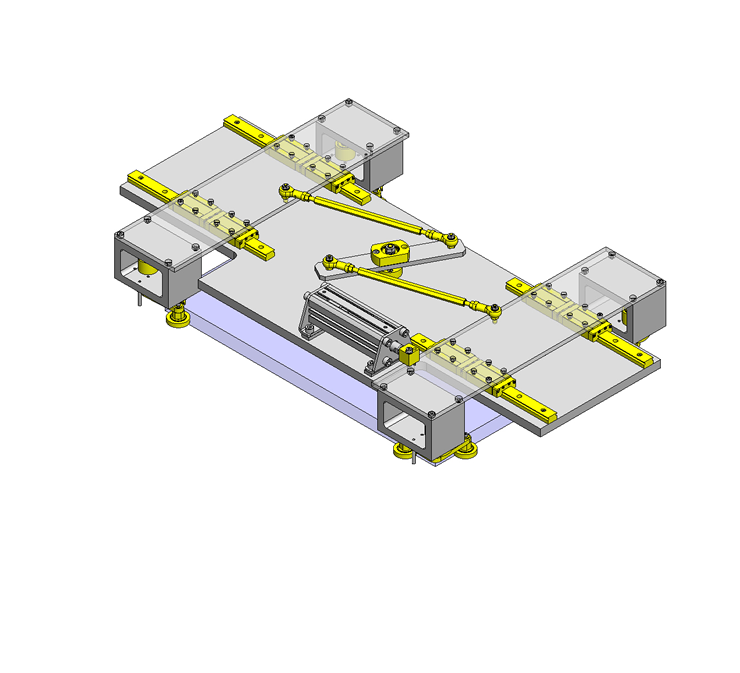

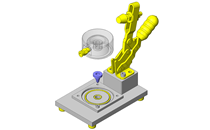

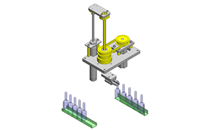

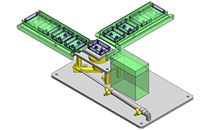

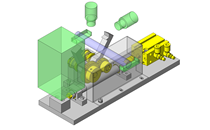

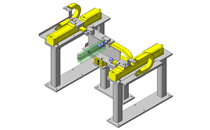

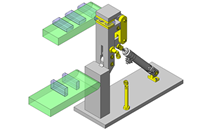

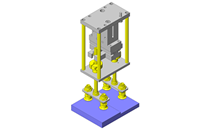

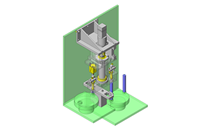

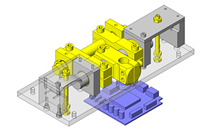

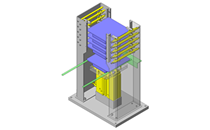

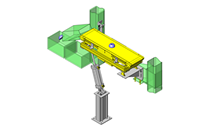

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

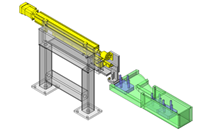

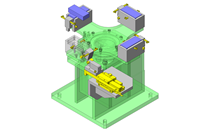

- (Objective) One cylinder clamps in four directions.

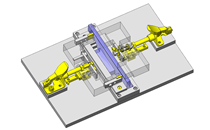

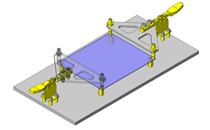

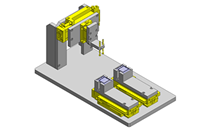

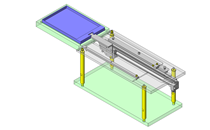

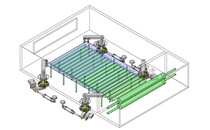

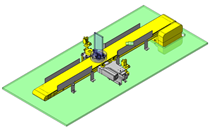

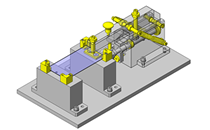

- (Operation) Pallets transferred on a roller conveyor are centered at working position.

Points for use

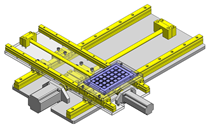

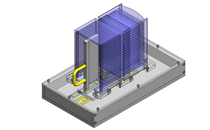

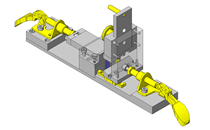

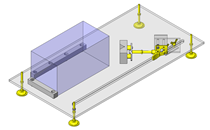

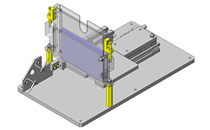

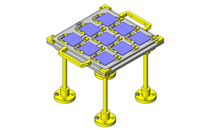

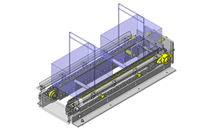

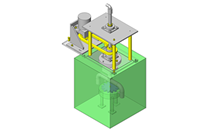

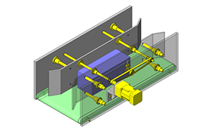

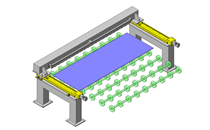

- Production line where the pallets are detected by photomicrosensor and stopped on the conveyor.

- Pallet evacuation mechanism is not needed.

Target workpiece

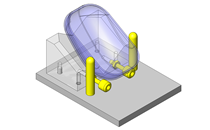

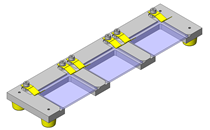

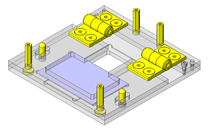

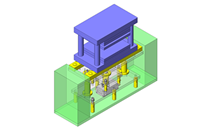

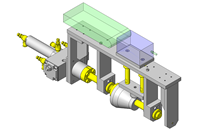

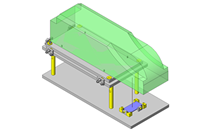

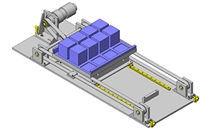

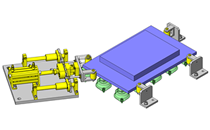

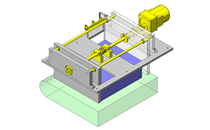

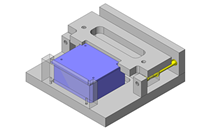

- Shape: Pallet

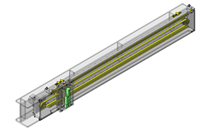

Size: W450×D300×H20mm

Weight:5kg

Design Specifications

Operating Conditions or Design Requirements

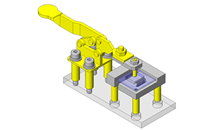

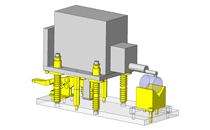

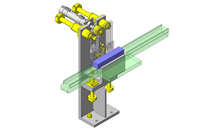

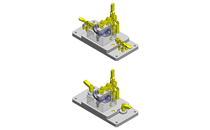

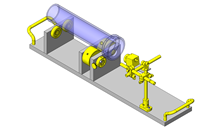

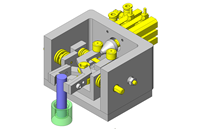

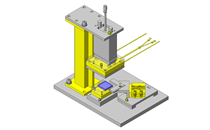

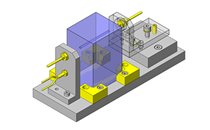

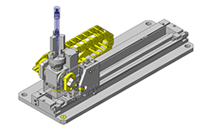

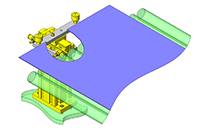

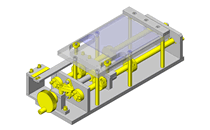

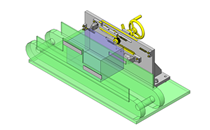

- Cylinder stroke: 75mm

- Clamp stroke: 5mm

Required Performance

- Conveyor stopping accuracy; ±45/300mm

Selection Criteria for Main Components

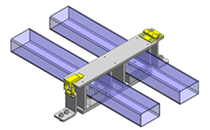

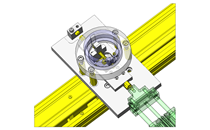

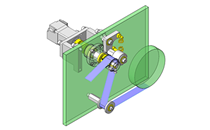

- Set the required linkage operation length (75mm) to be at 60 degrees to the center linkage connecting two sliders.

- Select a cylinder size according to friction coefficient and weight of the pallet.

Design Evaluation

Verification of main components

- Compare the process resistance force to the friction between the pallet and the roller conveyor.

- Here, the friction coefficient between the pallet and the roller conveyor to be 0.2.

- Required force for motion: Fp=5×0.2×9.8=9.8N of force can slide.

- From cylinder force chart,

Thrust of φ25 cylinder pull thrust when operation pressure 0.5 MPa Fs = 189 N - Process force withstandable: F = Fs - Fp, so F = 198 - 9.8 = 179.2 N

Therefore, the externally applied process force must be set to less than 179 N

Other Design Consideration

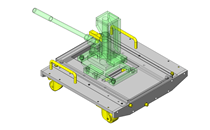

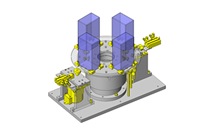

- During evacuation, the workpiece needs to stop on the conveyor within the center of four outside rollers.

- Determine the positions of 8 rollers according to pallet external dimensions.

- Determine the stroke based on roller evacuation position.

- Determine clamping force based on pallet weight and process force.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category

-

Relevant category