(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

- inCAD Library Home

- > No.000215 Separation Mechanism Utilizing Plate Cams

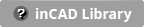

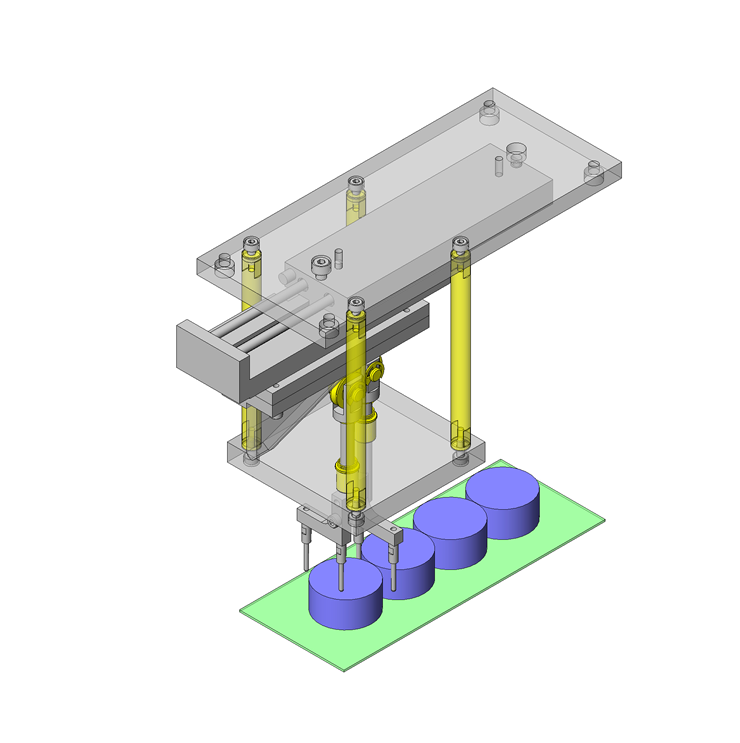

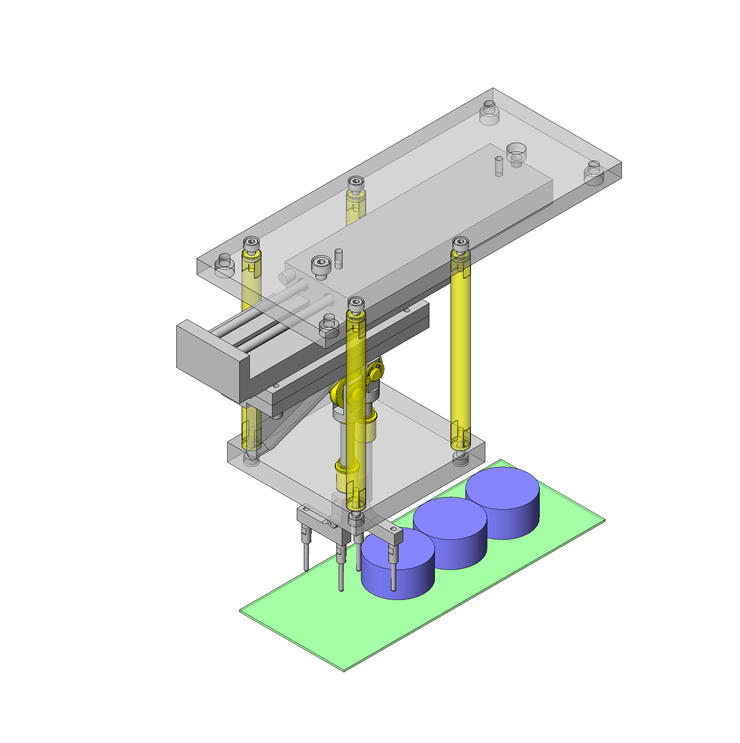

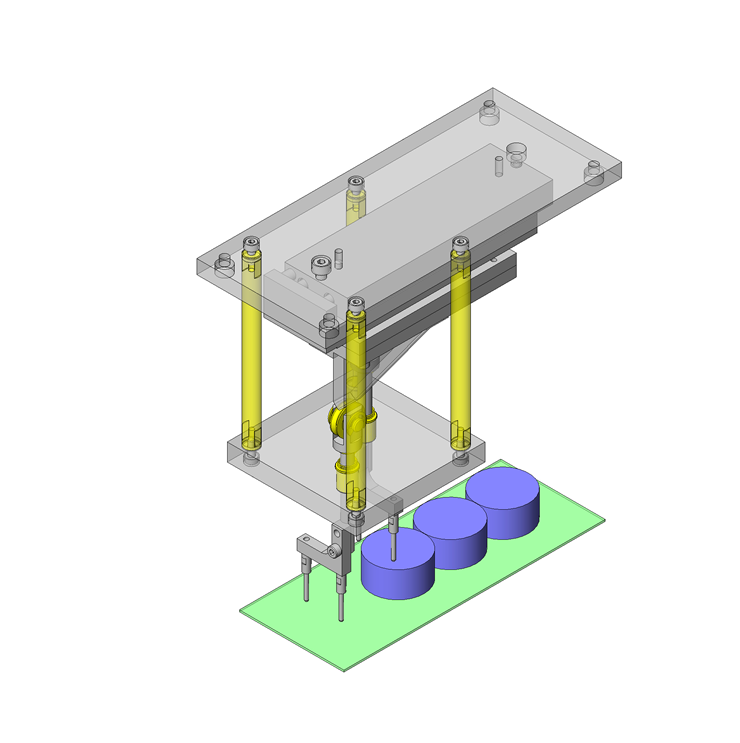

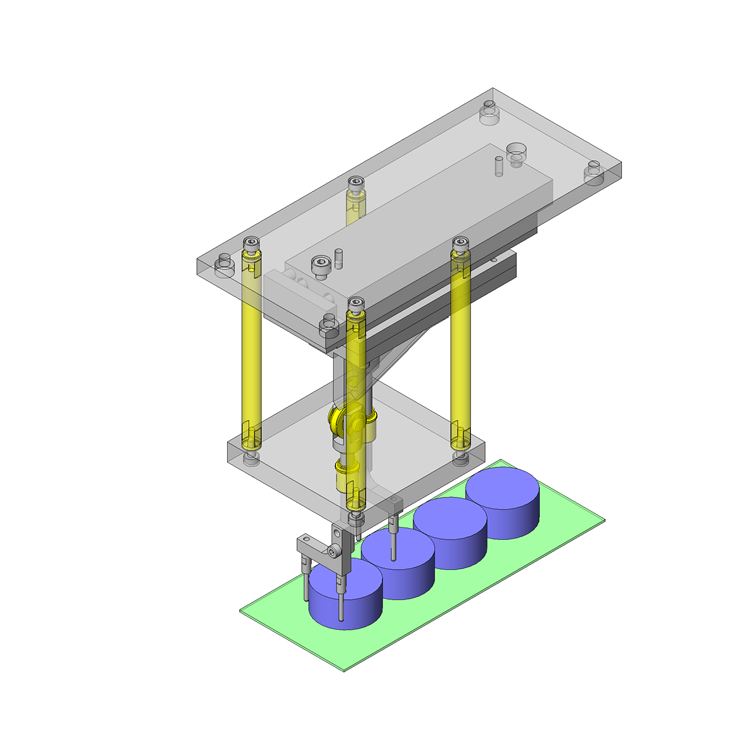

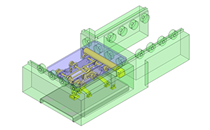

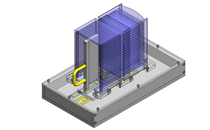

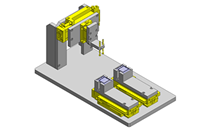

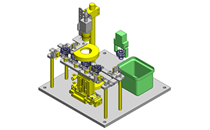

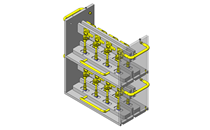

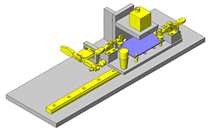

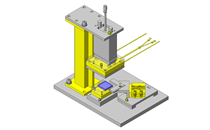

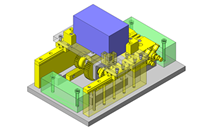

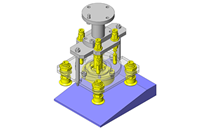

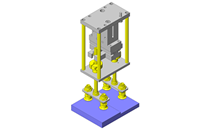

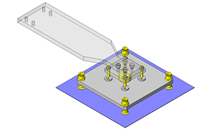

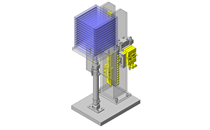

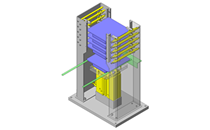

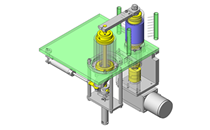

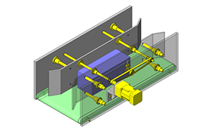

No.000215 Separation Mechanism Utilizing Plate Cams

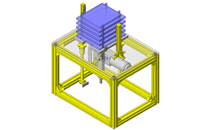

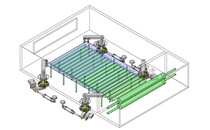

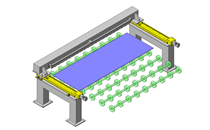

Continuous feeding mechanism utilizing plate cams.

Relevant category

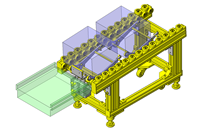

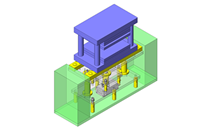

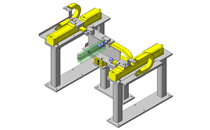

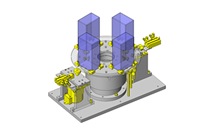

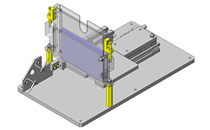

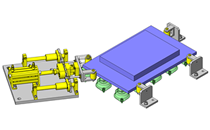

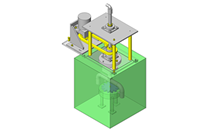

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

- Purpose

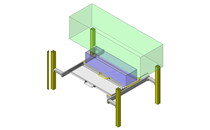

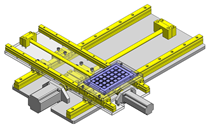

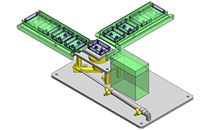

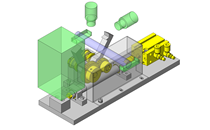

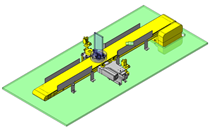

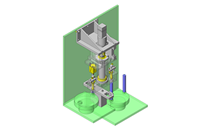

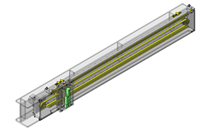

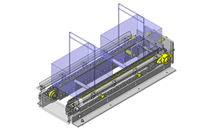

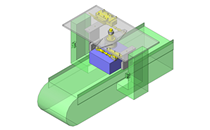

- Separates workpieces on the feeder.

- Operation

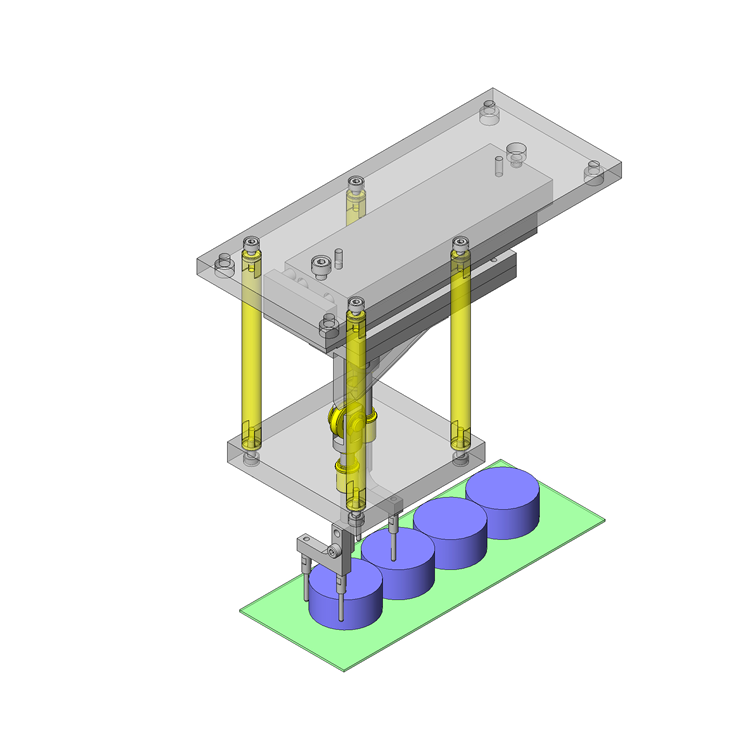

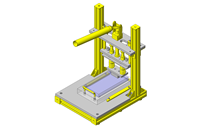

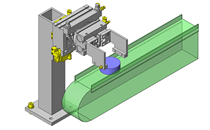

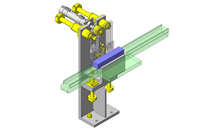

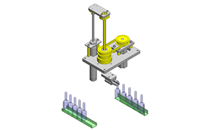

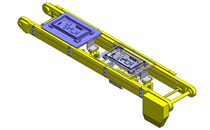

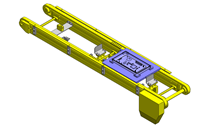

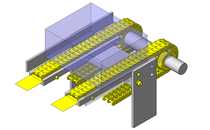

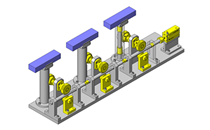

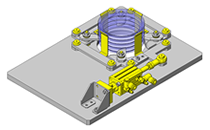

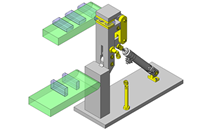

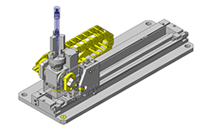

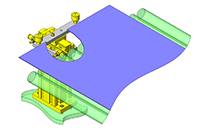

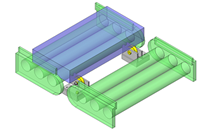

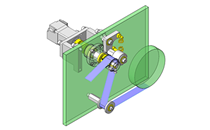

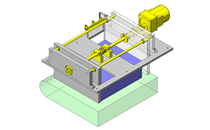

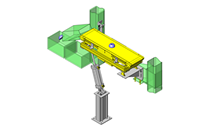

- As a single cylinder operates two sets of plate cams simultaneously, two sets of stoppers alternatively move up and down to separate work pieces.

Points for use

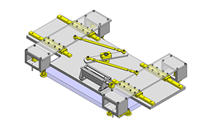

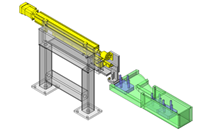

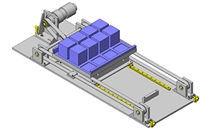

- To maximize efficiency the attachment at the tip of the stopper should be formed according to the work pieces shape.

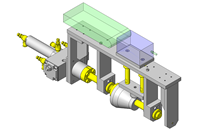

Target workpiece

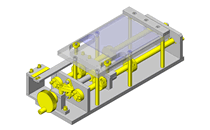

- Shape: round connector

- Size: φ30 x 15mm

- Weight: 0.1kg or less

Design Specifications

Operating Conditions or Design Requirements

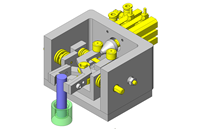

- Stopper pin stroke:15mm

- Cylinder stroke:50mm

- Outer dimensions:W74xD170xH175mm

Selection Criteria for Main Components

- A compression spring with a loose length of 25mm or longer and a compressed length less than 10mm is selected.

Design Evaluation

Verification of main components

- Selection of a compression spring

- Conditional value: free length of compression spring L1 = 30mm, solid length of compression spring L2=5.6mm

The length (free length) L3 of the spring required in this mechanism is L3>25mm

And its solid length is L4<10mm

Therefore,

The selected compression spring satisfies L1 > L3 and L2 < L4

Other Design Consideration

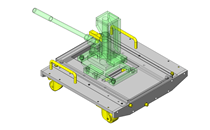

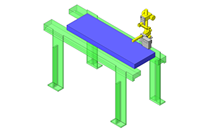

- This mechanism can be manufactured with a set of plate cams and a stopper unit.

- Depending on the mutual design of the two plate cams, it is possible to change the escape timing.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category